Addimetal – 3D Printing solutions designers | Metal Binder Jetting technology experts

Accelerate innovation through binder jetting additive manufacturing

The European reference in metal additive manufacturing K2-2, the binder jetting machine that redefines the standards of industrial 3D printing

Industrial Binder Jetting by Addimetal: A scalable metal AM solution

Binder Jetting: the future of metal additive manufacturing

Binder Jetting is one of the most advanced technologies in metal additive manufacturing. This process builds complex parts layer by layer by selectively depositing a liquid binder onto a bed of metal powder—without the need for support structures.

It enables the fast production of freeform geometries with exceptional precision, while significantly reducing material waste, thermal stresses, and production costs.

Binder Jetting stands out for its industrial scalability, its compatibility with a wide range of metal alloys, and its unmatched efficiency for series production.

Discover the K2‑2 metal binder jetting 3D printer

K2‑2: High‑performance metal binder jetting for R&D and production

The K2‑2 is a next‑generation Metal Binder Jetting 3D printer engineered for demanding environments—from advanced research labs to rapid prototyping and industrial‑scale metal part production.

Compact yet powerful, it features a high‑resolution printhead and an open architecture that provides full access to manufacturing parameters—ideal for materials research and process development.

Fully compatible with a wide range of metal and ceramic powders, the K2‑2 empowers users to independently qualify new materials.

Entirely developed in France, the K2‑2 embodies a commitment to technological sovereignty, agility, cost optimization, and environmental responsibility.

A scalable and open software for metal AM

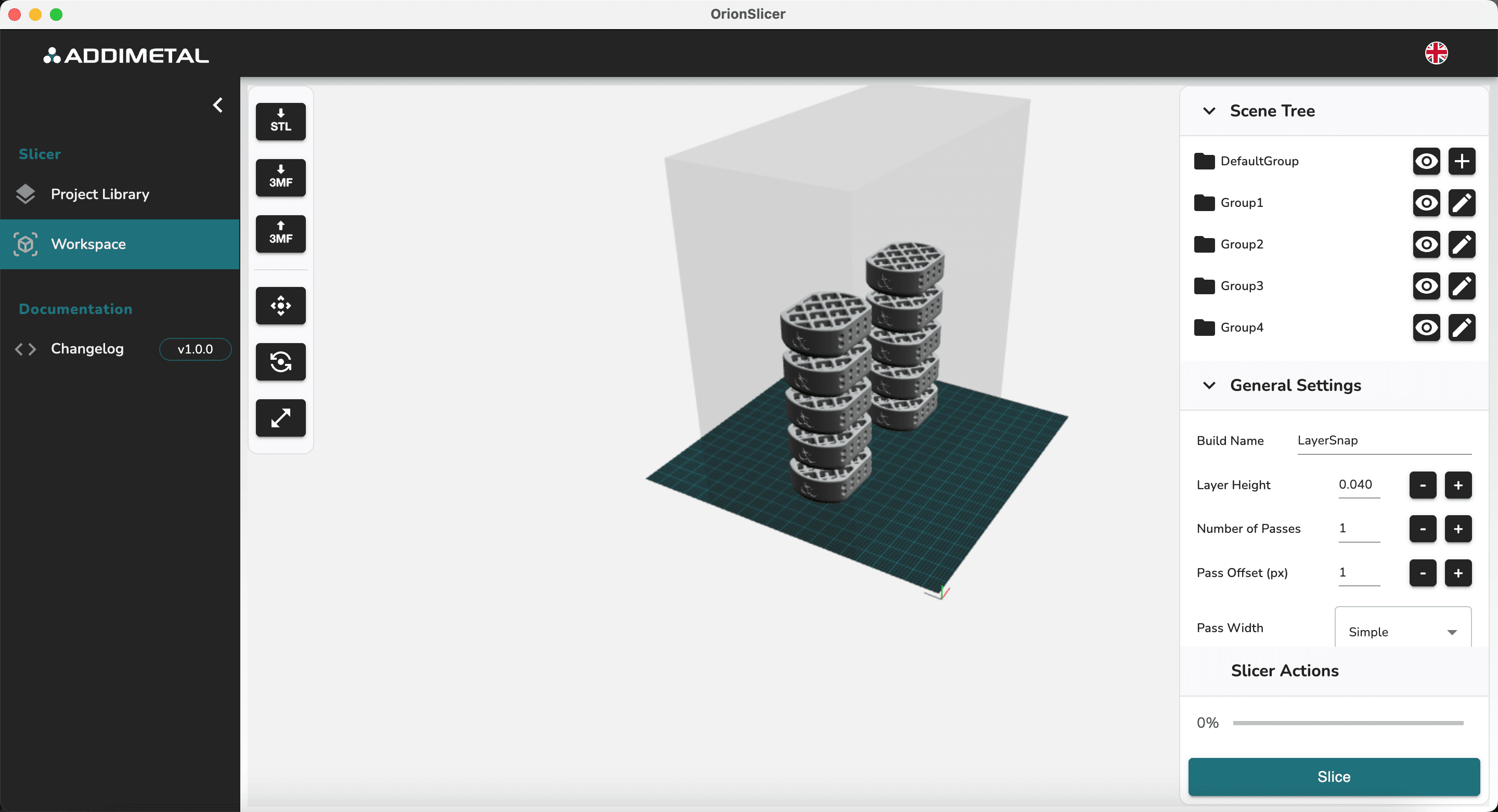

Orion : Full control over your digital manufacturing workflow

Orion is a software solution designed to streamline digital manufacturing—from file preparation to equipment control.

Built for both industrial environments and research labs, Orion combines an intuitive user interface with advanced tools for process customization, real‑time monitoring, and data analytics.

The platform gives users full control over their entire production workflow, including parameters, materials, and process flows—empowering them to optimize every stage of the additive manufacturing chain.

FOLLOW THE NEWS